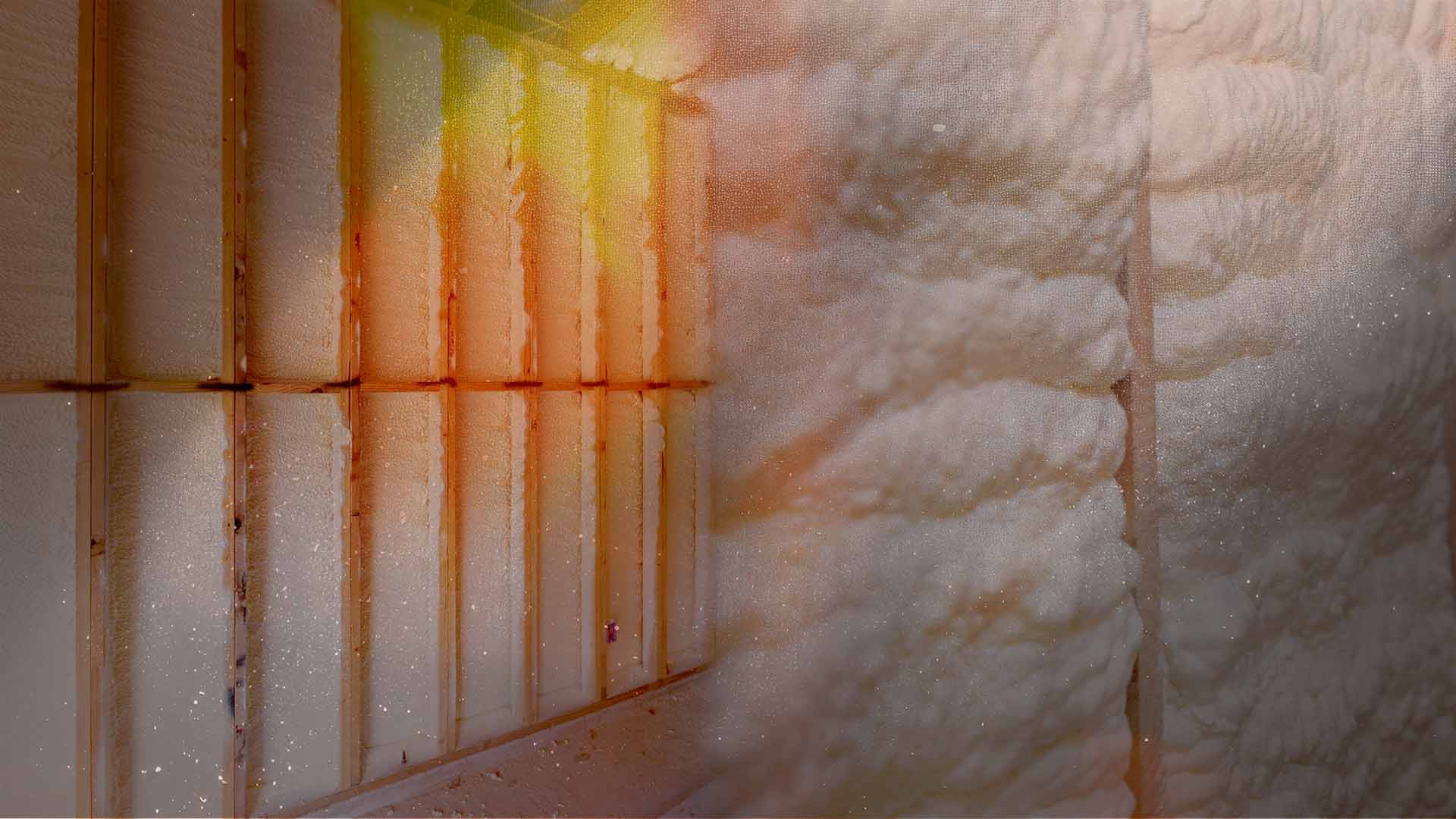

How Spray Foam Contractors Can Get More Leads Online in 2025

If you’re a spray foam contractor, being online isn’t optional anymore—it’s essential. The best product and spray technique won’t matter if potential customers can’t find you. This blog breaks down four simple but powerful ways to get more leads in 2025 using your Google Business Profile, a basic website, social media, and low-cost ads. If you’re strapped for time behind the gun, IPS can help with all of it—for free—with our E3 Alliance program.