INTRODUCTION

Spray foam insulation is an art, and getting it right requires finesse. This is even more apparent when you’re spraying in tough conditions. Below, we included some focused tips, visual guides, and a pragmatic checklist to help you when it comes to tackling tight spaces, inconsistent substrates, and spraying in extreme temps.

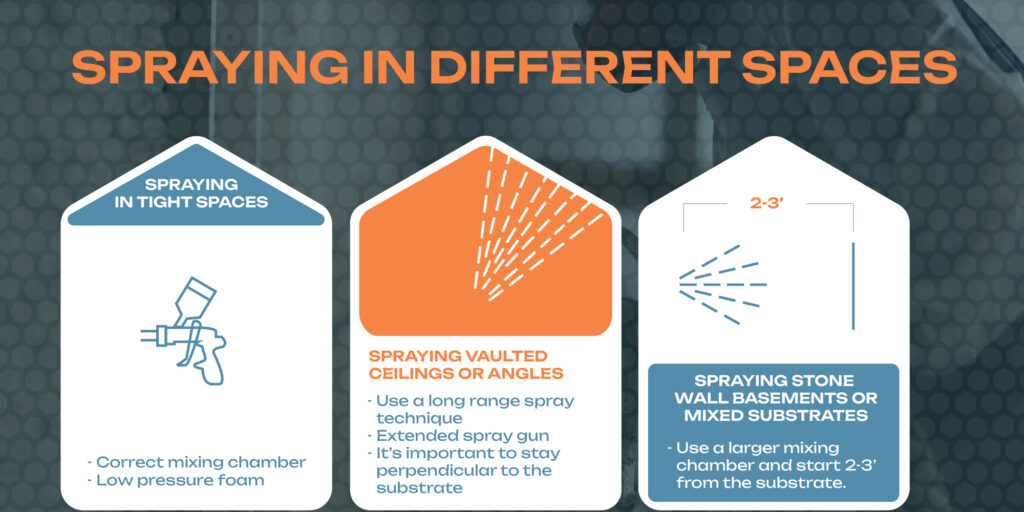

SPRAYING IN TOUGH SPACES

Techniques for Tight Areas

- Choosing The Correct Chamber Size Is Key: It’s important to understand how different conditions and spaces dictate which size chamber your should be spraying from. Your spray rates and patterns will be informed by your chamber size which will in turn affect how the foam is spraying in any given space. For example: Less flow combined with a tight pattern will give you the best results in tight spaces.

- Opt For Low Pressure Foam: Low pressure foam is going to help prevent any structural damage in tight spots after the foam sets. A good example of this would be window and door foam.

SPRAYING UNEVEN SURFACES

Before & During The Spray

- Prep The Surface: It’s critical that the substrate is cleaned and free of any debris as this will destabilize adhesion.

- Practice Multiple Spray Techniques: Having multiple spray techniques under your belt will give you the ability to master an array of situations from vaulted ceilings to attics, to basements with stone walls. If you can spray from a farther distance, this allows for a smoother finish.

IMPORTANCE OF MASKING

Masking is one of the most critical steps of the spraying process that should not be taken lightly. Even one window that has overspray can eat into your profits.

1. Preventing Overspray Damage

Spray foam tends to be very stubborn when it comes to removing it from unintentional surfaces. Proper masking will keep entry ways, doors, windows, floors, light fixtures etc… from getting foam on them. Which is costly from a time and financial standpoint to make right.

2. Ensuring a Professional Finish

Proper masking helps achieve clean, straight lines and a professional appearance. This attention to detail can make a significant difference in the overall aesthetics of the job and can enhance client satisfaction.

3. Saving Time and Money

By preventing overspray and the associated cleanup, masking can save a considerable amount of time and money. It’s far more efficient to spend time on thorough masking than to deal with the aftermath of overspray.

4. Choosing the Right Materials

Using the appropriate masking materials is key. For example, 1mil plastic might be suitable for light-duty protection, while 4mil plastic provides heavier-duty coverage for more demanding jobs. Selecting the right thickness can ensure adequate protection without unnecessary waste or expense.

5. Increasing Efficiency

With everything properly masked, you can spray more confidently and quickly, knowing that non-target areas are protected. This efficiency can lead to faster project completion times and the ability to take on more jobs.

Practical Tips for Masking:

• Use High-Quality Tape: Ensure the tape sticks well to surfaces and doesn’t leave residue behind.

• Cover Large Areas: Don’t skimp on the plastic or masking paper; cover larger areas to catch any potential overspray.

• Double Check Your Work: Before starting, walk around and double-check all masked areas to ensure everything is securely covered.

• Remove Masking Carefully: Once the spray foam has set, remove masking materials carefully to avoid pulling off any foam.

CHOOSING THE RIGHT FOAM

IPS Product Line: IPS 500EZ, IPS 500MAX, IPS 2000HFO, IPS 3000HFO

- IPS 500MAX: Is an excellent choice as it boasts a 120% expansion of initial volume sealing all cracks in tight spaces. Designed with the needs of professional applicators in mind, 500MAX provides superior adhesion and expansive coverage, making it ideal for vaulted ceilings.

ADAPT TO EXTREME TEMPERATURES

Keeping Control in Heat and Cold

- Oversee Material Temp: Spray foam needs to be maintained at specific temperatures, so make sure you are using thermal wraps or coolers to maintain the material temp.

- Know Your Blend: Change in weather will affect the reaction time of spray foam so it’s important to purchase the right blend for your application needs i.e. summer or winter blends for walls and or fast, regular, slow or extra slow for roofs.

- Hose Conscious: Be aware of how temperatures can affect your hoses, especially if they are laying on cold ground or hot pavement etc…

Safety Tip: Always ensure your setup respects local safety regulations, especially near electrical fixtures.

TOOLS AND MATERIALS FOR EVERY JOB

Recommended Products

- Trusted Spray Guns: Graco Fusion PC, Graco Fusion AP, Carlisle ST1, PMC AP-2

- Specialty Foams: Products – IPS – Innovative Polymer Systems (sprayips.com)

- Drill Bits for Chambers: Manufacturer specific

- Mold Release: Products – IPS – Innovative Polymer Systems (sprayips.com)

- Respiratory Protection: ULINE Search Results: 3m Respirator Mask,

- Full Body Spray Suit: SAS Safety Group | Moonsuit® Nylon/ Cotton Coverall (sassafety.com)

Expert Insight

Industry Expert Quote: “Understanding your materials, tools, and environment is critical to overcoming difficult spraying conditions” – Matt Scoggins, IPS MDC Manager / Technical Director